Vibratory feeders are automated devices used in various industries for efficient material handling and processing. They utilize vibration to transport and feed a wide range of materials, such as solid components, bulk solids, or even delicate items, ensuring a smooth and controlled flow. These feeders find application in diverse sectors, including manufacturing, food processing, pharmaceuticals, mining, and more. In the manufacturing industry, vibratory feeders are employed for precise assembly processes, aiding in the smooth and accurate feeding of small parts or components. Read More…

ERIEZ is a global manufacturer of an entire range of vibratory feeders and related machinery. We serve all the process industries, including food, chemical, pharmaceutical, ceramics, glass, packaging, metalworking, minerals processing and others.

Rodix manufactures vibratory feeder controls, inline track drives, drive bases, & bulk storage hoppers for part feeding systems. Our line of vibratory feeder controls feature variable amplitude, variable frequency, line-voltage compensation, UL/cUL Listed, CE Marked, and more. We have experience working with machine integrators, vibratory feed system builders, and manufacturers.

PPM Technologies Holdings, LLC is an innovative industry leader in the vibratory feeder industry. Our main focus has always been to provide our customers with high-quality products with the exact specifications for their needs. With our wide range of products, we are able to serve various industries.

If you are in need of quality vibratory feeders, we can help you out! At Hoosier Feeder, our philosophy is simple. We aim to put our customers first, get their requests right on the first try, communicate with them every step of the way, and deliver their products on time. We have experience working with a wide range of industries such as pharmaceutical, automotive, and food and beverage. For...

M&S Automated Feeding Systems creates parts feeders built and tested to each customer’s specific application. Fully equipped to design, fabricate and service a complete range of quality feeding equipment and specialized parts handling systems, including vibratory controls, conveyors, custom mechanisms, centrifugal feeder bowls, hoppers, vibratory inline feeders, sealing and vision systems.

More Vibratory Feeder Manufacturers

In the food processing industry, vibratory feeders are essential for conveying and aligning delicate fruits, nuts, and other food items during packaging and processing operations. They are also extensively used in mining to efficiently transport and separate bulk materials, enhancing productivity and minimizing manual labor. Their versatility and dependability make them invaluable in modern material handling, boosting productivity, reducing manual labor, and improving efficiency across various industries.

Components and Functioning of Vibratory Feeders

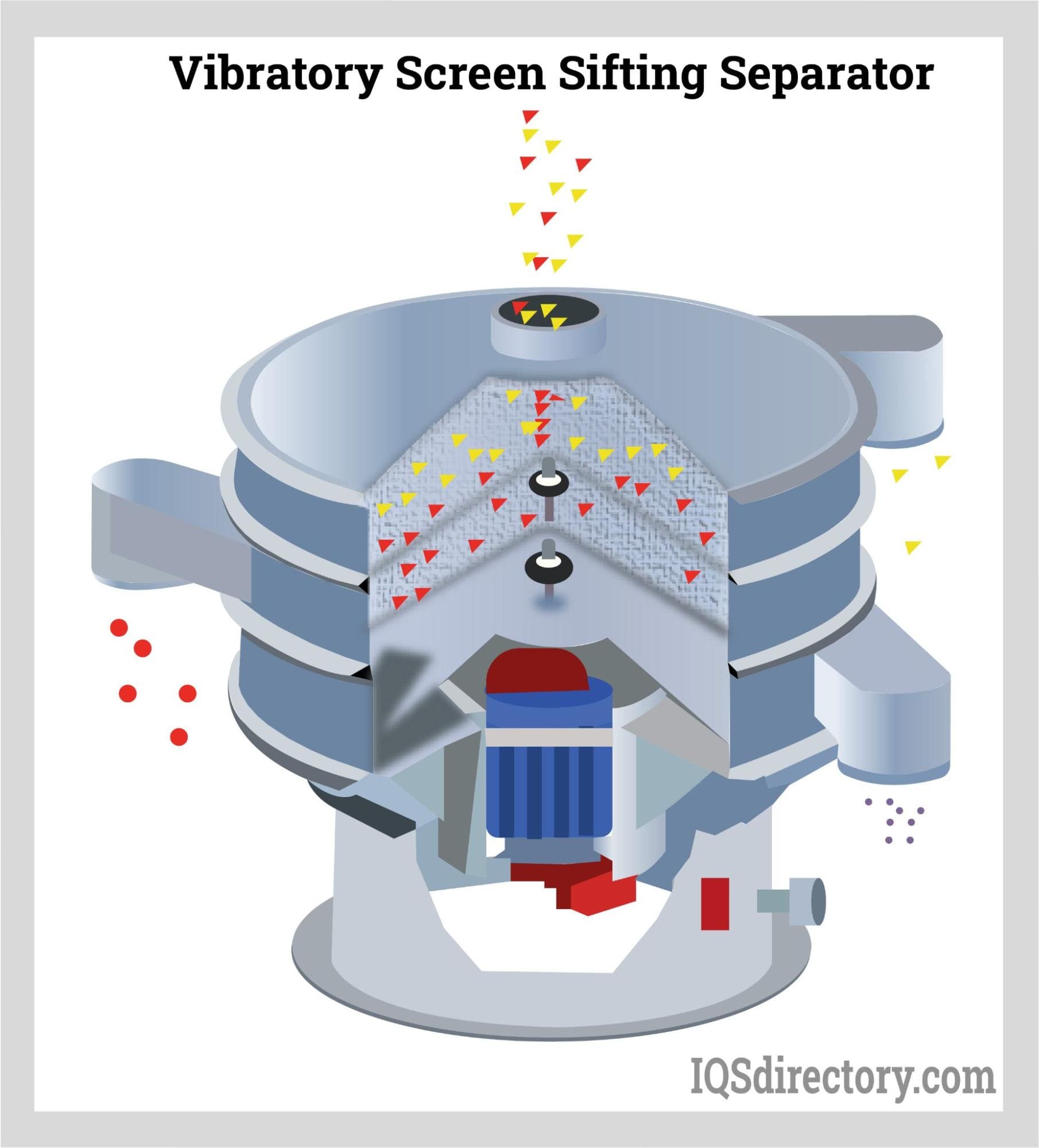

Vibratory feeders are composed of several essential components that work in harmony to create an effective system. At the core is the vibrating drive unit, which generates controlled vibrations. This unit typically features an electric motor with an eccentric weight or an electromagnetic drive to produce the necessary oscillating motion. This motion is transferred to the tray or trough, which holds and moves the materials. The tray is often tailored to the specific application to ensure optimal material flow. Springs are used to maintain stability and isolate vibrations, providing support and dampening excess vibrations for smooth operation. The support structure offers a solid foundation, ensuring the feeder’s stability and preventing unwanted movement. Together, these components form a vibratory feeder that efficiently and reliably transports materials. Whether aligning small parts, conveying bulk solids, or handling fragile items, the coordinated interaction of these components ensures a consistent and controlled flow, enhancing productivity and reducing material handling challenges.

Varieties of Vibratory Feeders

Vibratory feeders come in various designs and configurations, each tailored for specific applications. One popular variant is the bowl feeder, featuring a conical-shaped bowl that vibrates, prompting parts to move upward along spiral tracks. This design is widely used for orienting and feeding small parts, such as screws or electronic chips, in assembly lines. Another type is the tube feeder, commonly utilized in the pharmaceutical industry. Tube feeders employ a vibrating tube or cylinder to gently transport delicate tablets or capsules without causing damage. Linear feeders, conversely, use a linear motion to move items in a straight line, ideal for applications requiring precise positioning, like packaging or inspection processes. Additionally, specialized designs exist for specific applications, such as hopper feeders for bulk material handling or step feeders for sequential part feeding. Each type of vibratory feeder offers unique features and advantages, meeting the specific needs of various industries and applications.

Rules, Regulations, and Agencies

Regulations from various government agencies govern the creation and use of vibratory feeders in the United States. One key agency is the Occupational Safety and Health Administration (OSHA), which sets workplace safety standards. OSHA mandates that manufacturers and users of vibratory feeders adhere to safety regulations to protect workers from hazards like pinch points and risks during manual maintenance or troubleshooting. Additionally, the Environmental Protection Agency (EPA) oversees the environmental impact of vibratory feeders, focusing on noise emissions and potential pollution. Compliance with these regulations is vital for manufacturers to meet safety and environmental standards, avoid penalties, and ensure a safe working environment. Therefore, it is crucial for manufacturers and users of vibratory feeders to stay updated on the latest rules and regulations to ensure proper compliance and mitigate potential risks or legal issues.

Benefits of Vibratory Feeders

Vibratory feeders offer numerous benefits that enhance efficiency, productivity, and overall operational effectiveness. A major advantage is their ability to deliver a controlled and consistent material flow, ensuring a steady supply to downstream processes and minimizing disruptions. This leads to increased productivity by eliminating the need for manual feeding and reducing downtime. Their versatility allows vibratory feeders to handle a variety of materials, from small components to bulk solids, making them adaptable to different industries and applications. They can gently manage delicate or fragile items without causing damage, preserving the integrity of the products being processed.

Furthermore, vibratory feeders provide precise and adjustable feeding rates, enabling accurate control over the flow of materials. This precision minimizes waste, improves accuracy in assembly processes, and ensures high product quality. Additionally, vibratory feeders are typically low-maintenance, with simple designs and few moving parts, reducing the need for frequent repairs or replacements. They are durable, reliable, and easy to clean, resulting in lower operational costs. Overall, the benefits of vibratory feeders include increased productivity, improved efficiency, enhanced product quality, versatility in material handling, and cost-effectiveness, making them essential components in a wide range of industries.

Limitations of Vibratory Feeders

Although vibratory feeders have many advantages, they also come with certain limitations that should be taken into account. One significant limitation is their effectiveness in handling materials that tend to clump, bridge, or jam. These feeders can struggle with sticky or cohesive substances that stick to the trough or tray, obstructing the material flow. Additionally, some materials can cause significant wear and tear on feeder components, resulting in maintenance problems and potential downtime. Vibratory feeders also have restrictions related to size and weight, limiting their use with larger or heavier materials. It is crucial to evaluate the properties of the materials being processed and consider these constraints when choosing or designing a vibratory feeder system. Addressing these limitations often requires customization, such as applying specialized coatings, modifying tray designs, or adding extra features to manage specific material challenges effectively.

Overcoming Limitations

Manufacturers of vibratory feeders are actively addressing the limitations of these devices by continually researching and developing innovative solutions to improve their performance and functionality. One strategy involves creating enhanced surface coatings and lining materials that prevent sticky or cohesive substances from adhering, thereby reducing the risk of clogging or bridging. Additionally, customized tray designs with features like angled surfaces or adjustable gates are being introduced to ensure the smooth flow of challenging materials. Manufacturers are also advancing control systems, allowing for more precise adjustments of vibration intensity, frequency, and timing to better handle different materials. Furthermore, the integration of advanced monitoring and diagnostic technologies provides real-time feedback and predictive maintenance, minimizing downtime and boosting overall operational efficiency. These collective efforts aim to enhance the reliability, versatility, and performance of vibratory feeders, enabling them to overcome existing limitations and meet the evolving demands of various industries.

Choosing the Right Vibratory Feeder

Selecting the appropriate vibratory feeder for a specific application involves careful consideration of several key factors. First, assess the characteristics of the materials to be handled, including their size, shape, density, and flow properties. It is crucial to choose a feeder that can effectively manage these specific material requirements. Determine the desired feed rate, which is the amount of material to be processed per unit of time. Additionally, consider the environmental conditions where the feeder will operate, such as temperature, humidity, and the presence of corrosive substances, to ensure the feeder’s durability and longevity.

Consulting with experts and manufacturers, conducting thorough testing, and seeking recommendations based on industry best practices can provide valuable insights into selecting the right feeder. Also, consider the feeder’s reliability, ease of maintenance, and the availability of spare parts and technical support. By carefully evaluating these factors, you can select a vibratory feeder that meets the specific requirements of your application, ensuring optimal performance and productivity.

Integration with Automation Systems

Vibratory feeders are essential for automating material handling and ensuring smooth workflows. When integrated with automation systems, such as robotic assembly lines or PLC-controlled processes, they enable synchronized and precise material feeding. Incorporating sensors and feedback mechanisms allows the automation system to communicate with the vibratory feeder, regulating material flow based on real-time needs. This integration enhances control and adaptability, optimizing production rates and minimizing errors. Additionally, vibratory feeders can be programmed to sync with other machinery, initiating feeding at specific intervals or in response to signals from the automation system. This synchronization ensures continuous material flow, boosting the overall efficiency and productivity of the automated process. By improving accuracy and speed and reducing manual labor, the integration of vibratory feeders with automation systems allows operators to focus on more critical tasks.

Maintenance and Troubleshooting

To ensure optimal performance and longevity of vibratory feeders, they require proper maintenance and troubleshooting practices. Regular maintenance should involve scheduled inspections to identify and address any signs of wear, damage, or loose components. Routine cleaning is also essential to remove debris and build-up, with the frequency of cleaning dependent on the specific application and material accumulation, ranging from daily to weekly or as needed. Lubricate moving parts, such as bearings or drive mechanisms, according to the manufacturer’s recommendations. Monitoring vibrations and noise levels can help detect abnormalities or potential issues. Troubleshooting involves identifying and resolving common operational problems, such as material blockages, incorrect feeding rates, or irregular vibrations. It is crucial to consult the feeder’s manual and follow recommended troubleshooting procedures. For more complex issues, involving a trained technician or contacting the manufacturer’s support team may be necessary. Adhering to regular maintenance and prompt troubleshooting practices ensures optimal performance, minimizes downtime, and extends the lifespan of vibratory feeders, thereby maximizing their efficiency and productivity in material handling operations.

Future Outlook

The future of vibratory feeders is filled with promising advancements. Technological innovations are paving the way for feeders to become more intelligent and adaptable. By incorporating advanced control systems like artificial intelligence and machine learning algorithms, these feeders could analyze and respond to changing material characteristics in real-time, optimizing their performance and efficiency. Improvements in sensor technology are likely to enhance the monitoring and adjustment of parameters, ensuring precise and reliable feeding. The development of new materials and surface coatings will help address wear and maintenance issues, extending the lifespan and reliability of vibratory feeders. Additionally, integrating Industry 4.0 concepts will enable connectivity and data exchange, facilitating predictive maintenance and remote monitoring. As industries increasingly focus on automation, productivity, and efficient material handling, vibratory feeders are set to play a crucial role in the future of manufacturing, processing, and material handling, offering enhanced performance, flexibility, and better integration with advanced technologies.

Choosing the Right Vibratory Feeder Manufacturer

To achieve the best results when purchasing vibratory feeders, it’s essential to compare multiple companies using our directory of vibratory feeder manufacturers. Each manufacturer has a business profile page showcasing their expertise and capabilities, along with a contact form for direct communication to request more information or a quote. Utilize our patented website previewer to quickly understand each company’s specialties by reviewing their business websites. Finally, use our straightforward RFQ form to contact several vibratory feeder businesses simultaneously.

Check out our Recycling Equipment website

Check out our Vacuum Cleaners website

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services