Unlike pneumatic conveying, screw conveying and standard belt conveying, vibrating conveying offers solutions for moving delicate or sticky food materials without causing liquefying or damage due to shearing or rough handling. Read More…

ERIEZ is a global manufacturer of an entire range of vibratory feeders and related machinery. We serve all the process industries, including food, chemical, pharmaceutical, ceramics, glass, packaging, metalworking, minerals processing and others.

Rodix manufactures vibratory feeder controls, inline track drives, drive bases, & bulk storage hoppers for part feeding systems. Our line of vibratory feeder controls feature variable amplitude, variable frequency, line-voltage compensation, UL/cUL Listed, CE Marked, and more. We have experience working with machine integrators, vibratory feed system builders, and manufacturers.

PPM Technologies Holdings, LLC is an innovative industry leader in the vibratory feeder industry. Our main focus has always been to provide our customers with high-quality products with the exact specifications for their needs. With our wide range of products, we are able to serve various industries.

If you are in need of quality vibratory feeders, we can help you out! At Hoosier Feeder, our philosophy is simple. We aim to put our customers first, get their requests right on the first try, communicate with them every step of the way, and deliver their products on time. We have experience working with a wide range of industries such as pharmaceutical, automotive, and food and beverage. For...

M&S Automated Feeding Systems creates parts feeders built and tested to each customer’s specific application. Fully equipped to design, fabricate and service a complete range of quality feeding equipment and specialized parts handling systems, including vibratory controls, conveyors, custom mechanisms, centrifugal feeder bowls, hoppers, vibratory inline feeders, sealing and vision systems.

More Vibrating Feeder Manufacturers

Vibrating feeders offer low-maintenance parts and material handling, as vibratory conveyors and bowls use no moving parts except the vibrating drive installed beneath the bowl or feeder pan, away from contaminating materials.

There are two main types of vibrating feeders: vibrating bowl feeders and vibrating conveyors. Vibrating bowl feeders are used extensively by small parts manufacturers as an extremely efficient means of orienting products for further finishing or for distribution. Originally designed by pharmaceutical companies to count, sort and organize pills, bowl feeders also orient fasteners, ammunition, o-rings, molded rubber parts, toothpaste caps and many other small parts for packaging or finishing.

Vibrating conveyors, on the other hand, are used for powder and bulk material handling in a range of industries, including pharmaceutical, agricultural and food processing. Additionally, recycling industries use vibratory conveyors extensively to convey and sort materials such as plastic, wood, crushed cement and metals for reclamation. Overall, vibrating feeders provide an ergonomic solution to monotonous and physically strenuous sorting tasks.

Vibrating bowl feeders are a type of parts feeder used in parts manufacturing to align finished or semi-finished parts for final processing or packaging. Vibrating bowl feeders are metal, silicone or plastic bowls equipped with a vibrating drive beneath the bowl, where the bowl is mounted to the base. A ramped ridge runs up along the edge of the bowl in a spiral, leading to the outfeed area.

Bowl feeders vibrate in a circular motion, driving parts up the ridge, which is usually designed for a specific part; it narrows as it reaches the outfeed, forcing parts to form a single-file uniform line.

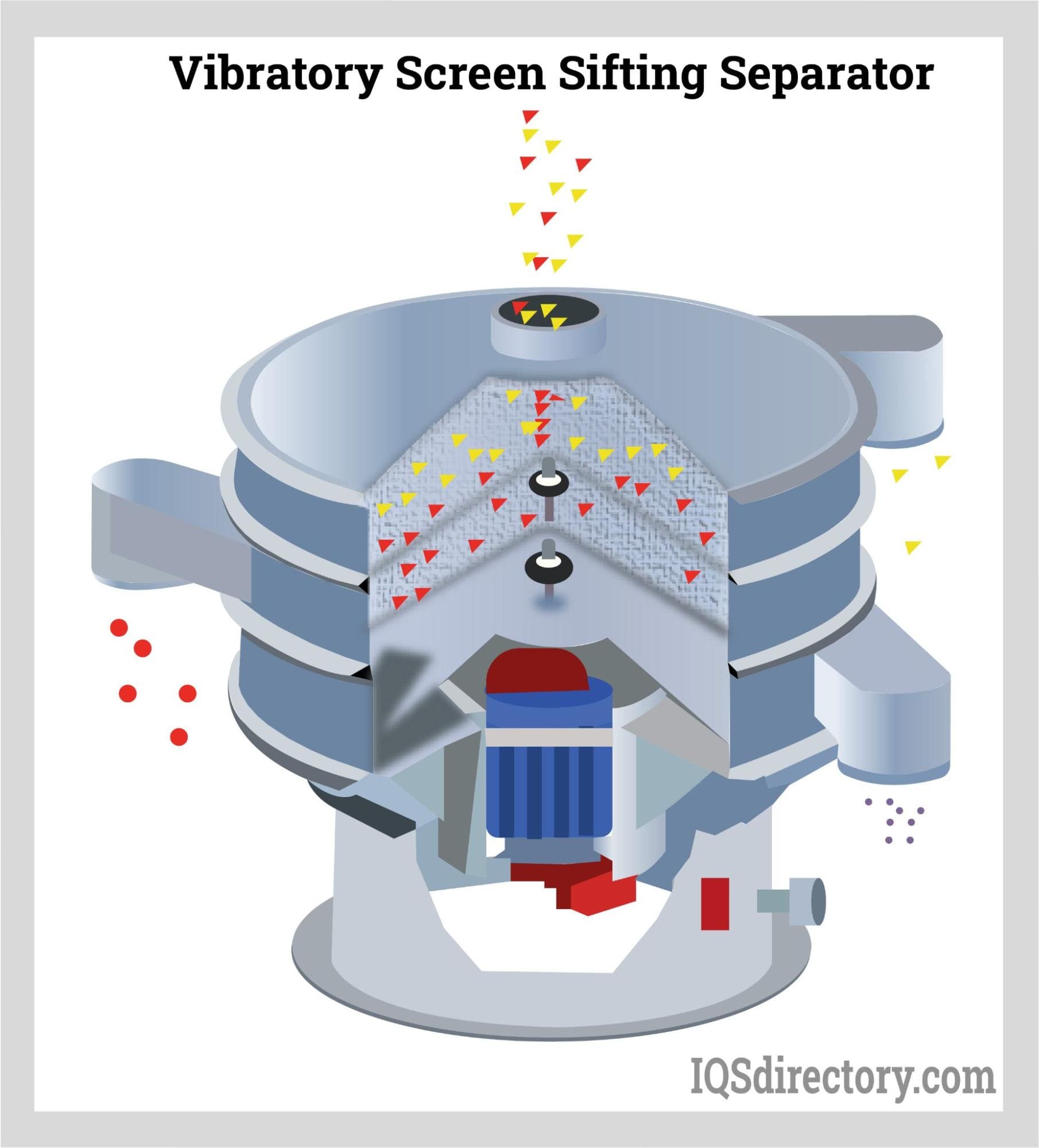

Vibrating conveyors encompass a wider range of troughs, vibrating screens and trommel screens which convey and/or sort bulk materials during processing. Vibrating conveyors are metal troughs which vibrate in one direction, conveying powder bulk solids or heterogenous mixtures from one process to another.

Some vibrating conveyors have ultra-low vibrations designed specifically for solids which are delicate, sticky or may liquefy, such as gummy bears or lettuce. Trommels, or trommel screens are vibrating screens which help sort small particles from large particles.

Rotary trommels, a large tumbler design, aid in gravel processing and recycling; trommel magnets are often used in conjunction with metal recycling rotary trommels to help sort ferrous materials from non-ferrous materials. Continuous flatbed trommels may have screens or filtering devices which sort particles of different sizes as large particles are conveyed to containment or further processing.

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services