Vibratory Feeder Manufacturers Serving Alaska

Use our thorough list of vibratory feeder manufacturers and suppliers in Alaska to examine and sort top vibratory feeder manufacturers with previews of ads and detailed descriptions of each product. Any vibratory feeder manufacturers can provide vibratory feeder products to meet your company's specific qualifications. An easy connection to reach vibratory feeder manufacturers through our fast request for quote form is provided as well. This source is right for you whether it's for bowl feeders, grizzly screens, or any other vibratory feeder needs.

Companies Serving Near Alaska

Kinergy Corporation

Louisville, KY | 502-366-5685Kinergy is a leading manufacturer of Vibratory Feeders and other material handling equipment. With over 50 years of experience in the industry, the company has built a reputation for delivering innovative and reliable solutions to meet the unique needs of each customer.

Kinergy’s Vibratory Feeders are designed to provide a consistent and reliable flow of materials, ensuring maximum...

Balers

Balers Compactors

Compactors Granulators

Granulators Grapplers

Grapplers Metal Shears

Metal Shears Pulverizers

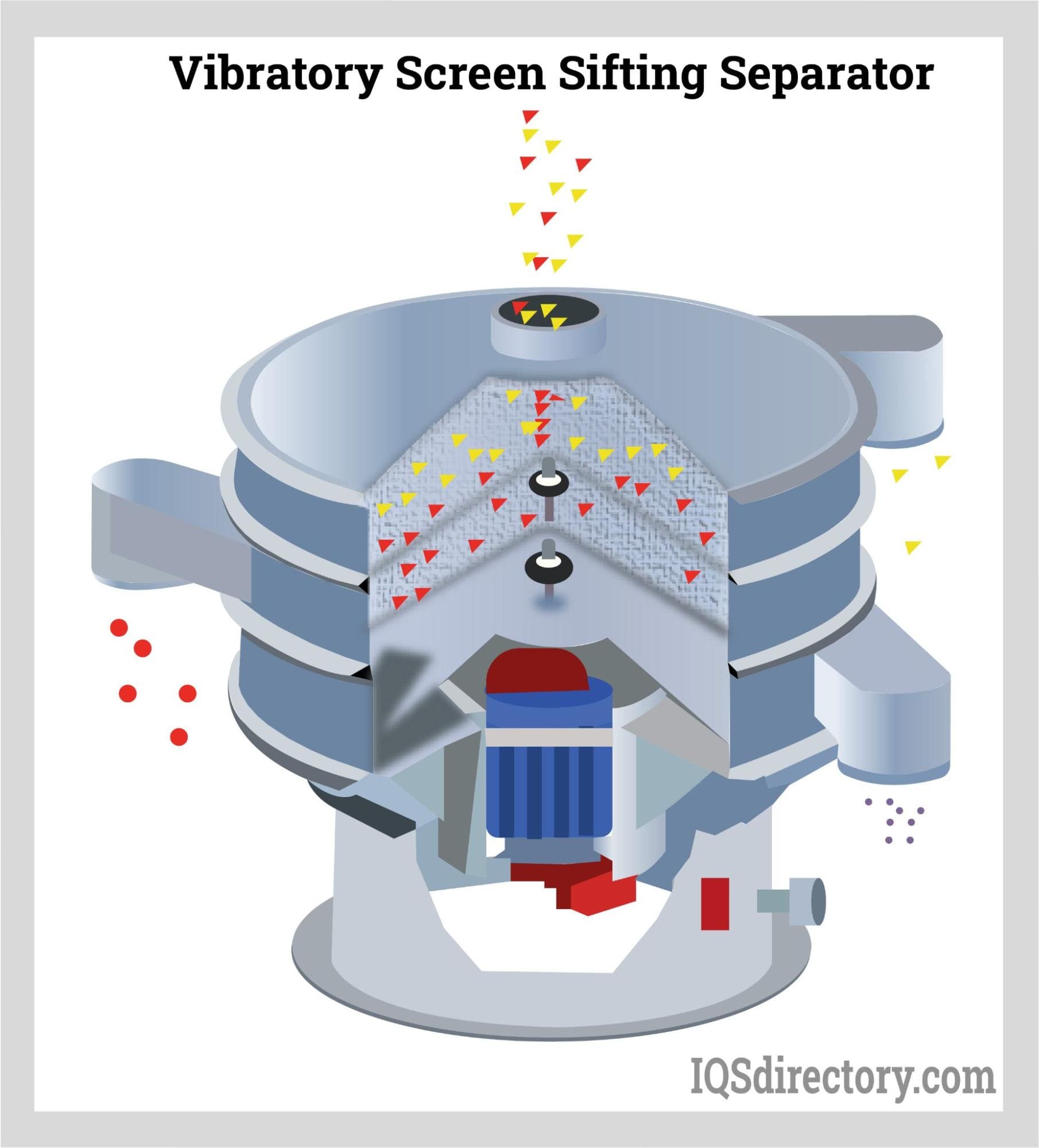

Pulverizers Separators

Separators Shredders

Shredders Vibratory Feeders

Vibratory Feeders Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services